How do we approach sustainability at Plastenco Design?

Design largely influences the potential level of environmental impacts of products (literature suggests that up to 80% of impacts are predetermined at the design stage)[1]. At Plastenco, we are fully aware of the responsibility we bear and therefore strive to optimize all our processes to minimize our environmental impact. However, we are also not indifferent to the economic and social pillars of sustainability; in our projects we strive to create stories and connect the community. This article will give you an insight into how we approach sustainability and what steps we take to meet the ESG expectations of our clients and partners.

Our approach to sustainability

Openness

Communication and data-driven decision-making is essential to us, so at Plastenco we have chosen to transparently communicate the origin of our materials, our manufacturing process and the environmental impact of our products. Our actions are thus to some extent ahead of the new Regulation (EU) 2024/1781 on ecodesign for sustainable products, which came into force on 18 July 2024, but products that meet the new criteria are not expected to start appearing on the market until the second half of 2026[2].

Materials

One of the key aspects is the careful selection of materials. We try to favour recycled, local materials that can be reused at the end of their life cycle. For this reason too, we are trying to optimise the labelling of each material, recording its origin, specific composition and properties using a material sheet inspired by the Digital Product Passport (DPP)[3], which will be one of the key requirements in the field of eco-design in the future.

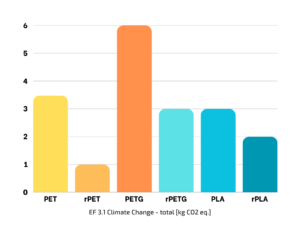

Figure 1: Comparison of the environmental impacts of different materials according to the Environmental Footprint 3.1 characterisation model, climate change category, based on 1 kg of material. Ecoinvent datasets version 3.9.1 and Sphera databases were used to represent the impact, or from publicly available literature.

Carbon footprint

We also include an indicative carbon footprint of the print itself, as well as the material used (cradle to gate system), as part of each product. The calculation is based on the Environmental Footprint 3.1 characterisation model[4], which is standardly used in Environmental Product Declarations (EPDs). The greenhouse gas emission intensity (emission factors) was drawn from the Ecoinvent database version 3.9.1[5], and the emissions of the average energy mix in the Czech Republic were chosen to represent the impact of the electricity used.

Heat recovery

In order to keep our materials under control as much as possible, we now offer the option of taking back our own products for which you have no further use. We will then take care of recycling it and turning it into a new product or putting it to another use, for example through the Reborn Designplatform . In this way, we can together prevent the consumption of new raw materials and keep the recycling process under control. These are large-format products manufactured from autumn 2024 onwards – you can find out which ones in our catalogue.

Individual approach

We approach our clients and every proposal conscientiously and with full commitment. We always try to find the best possible solution to the satisfaction of all parties and the environment in which we live.

Research, innovation and experience

Plastenco is not afraid to innovate and engage in technological challenges (TAČR Trend FW09020011)[6], pushing the boundaries of 3D printing to a new level and having access to the latest technologies. It is also important for us to cooperate and share know-how with our partners such as the technology company Lavaris, the Faculty of Architecture of the Czech Technical University or the Reborn Design platform .

Community projects and cooperation

Education, collaboration and support for community projects are also important aspects of sustainability. For this reason, we organize workshops, participate in conferences, and collaborate with a large community of printers in the Czech Republic, with whom we have jointly printed Pla(s)teosaurus. We look forward to more projects that are aligned with the Sustainable Development Goals (SDG’s)[7] and help our clients meet their non-financial ESG reporting goals.

Conclusion

Are you interested in our approach? Together we can achieve more, don’t hesitate to contact us.

The project FW09020011 „Development of large-format 3D printing from recycled plastics and its commercial application in innovative eco-design“ is co-financed with state support from the Technology Agency of the Czech Republic within the TREND Programme / Subprogramme 2 „Newcomers“.

Sources:

[1] Ministry of the Environment. Ecodesign; Ministry of the Environment: Prague, Czech Republic, 2003; ISBN 80-7212-230-4.

[2] Commission Regulation (EU) 2024/1781 on ecodesign requirements for energy-related products. Available online: https://eur-lex.europa.eu/legal-content/CS/TXT/?uri=CELEX%3A32024R1781&qid=1719920289539

[3] European Commission. Ecodesign for Sustainable Products Regulation; European Commission: Brussels, Belgium. Available online: https://commission.europa.eu/energy-climate-change-environment/standards-tools-and-labels/products-labelling-rules-and-requirements/ecodesign-sustainable-products-regulation_en

[4] Environmental Footprint 3.1. Available online: https://eplca.jrc.ec.europa.eu//EnvironmentalFootprint.html

[5] Ecoinvent Database. Available online: https://www.ecoinvent.org/

[6] Project FW09020011 „Development of large-format 3D printing from recycled plastics and its commercial application in innovative eco-design“ is co-financed with the state support of the Technology Agency of the Czech Republic within the TREND Programme / Sub-programme 2 „Newcomers“.

[7] United Nations. Sustainable Development Goals; United Nations. Available online: https://sdgs.un.org